November 2024 NEWSLETTER

Explore the latest innovations, opportunities, and insights in this month's newsletter! Read how one climate tech startup received funding and exciting testing results, while others are adding new products. Plus, there are lots of grands and funding opportunities this month. As always, we have startup opportunities and events to add to the calendar!

Hudson Valley construction-tech startup wins a grant from the Department of Energy

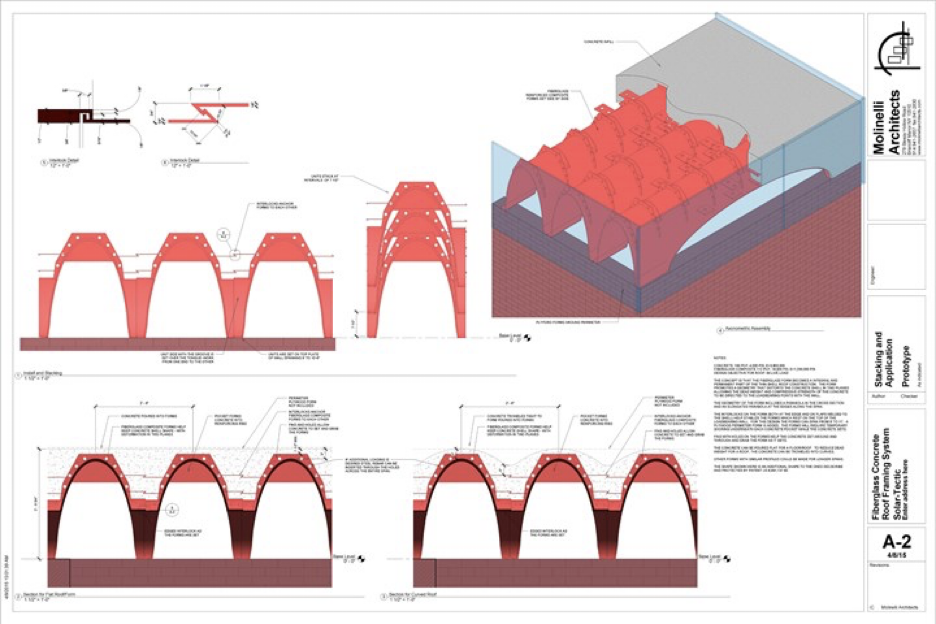

ST Bungalow LLC, based out of Garrison, NY, in Putnam County and Molinelli Architects based out of Briarcliff Manor in Westchester county, has partnered with the Sustainable Materials and Manufacturing Alliance for Research Technology (SM2ART), a partnership between Oakridge National Lab and U of Maine, to research, prototype, and certify an innovative construction technology product that essentially takes recycled materials and makes them into formwork that stays in place while reinforcing concrete, thereby replacing rebar.

After completing phase 1 of the grant with great success, , the team has officially been awarded another – phase 2– grant in non-dilutive funding by the U.S. Department of Energy’s Advanced Materials and Manufacturing Technology Office. The grant will allow for actual physical scaled up prototypes and testing of the product made from recycled materials, including wind turbine blades. Currently the wind turbine blade industry is faced with a bottleneck: there is no product that makes use of recycled wind blade material with a large enough consumption that can drive circularity by making it actually profitable. With the new phase 2 grant award ST Bungalow LLC is well on its way to meet this challenge.

This milestone achievement marks a significant step forward in sustainable construction technology, with Phase 1 of the project already yielding impressive results. The initial phase involved detailed computer modeling, leading to a Phase 2 grant, which focuses on producing physical prototypes, scaling production, and obtaining necessary certifications.

The patented technology marks a significant breakthrough in building and construction, offering a stay-in-place (SIP) composites formwork system designed to reinforce concrete flatwork, such as floors, roofs, and infrastructure like bridge decking. Unlike traditional systems that rely on steel rebar or fiber-reinforced polymer (FRP) rebar, this innovative formwork uses non-ferrous materials, completely eliminating the need for steel. By replacing steel with recycled wind turbine blades, ST Bungalow LLC's system not only reduces the carbon footprint of buildings but also addresses both the economic and environmental challenges faced by modern construction. The extremely low cost of recycled wind blade material combined with the patented innovation means a much cheaper way of reinforcing concrete that also is sustainable.The formwork system delivers significant cost savings by eliminating the need for extensive labor to place rebar. The stay-in-place design reduces time and complexity on-site, while also cutting down on material costs due to the use of recycled composites. This innovative approach allows concrete to function optimally in compression, while meeting new environmental standards required.

The patented system offers a solution to one of the growing challenges in the wind energy industry: what to do with retired wind turbine blades. These large FRP structures have long posed a bottleneck for recycling efforts. By incorporating these materials into construction, this formwork system helps drive circularity in both the wind and boating industries. The recycled composites not only provide cost-effective building materials but also contribute to the reduction of industrial waste.

With the growing demand for sustainable alternatives, this new formwork system is poised to be a game changer in the construction industry. Its non-ferrous composition avoids common issues like steel rebar corrosion and expansion, which are becoming increasingly problematic due to the intensifying effects of climate change. Uniquely, it is the only concrete reinforcement system made from recycled materials, offering a truly innovative solution for sustainable building practices.

With a larger grant awarded for phase 2 of development, the collaboration between ST Bungalow, Molinelli Architects, and SM2ART is now focusing on creating physical prototypes and scaling the technology for wider use. The patented technology has already been issued and allowed by the U.S. Patent Office, and is poised to transform how contractors and architects approach sustainable building solutions.

In a recent interview with founder Ashok Chaudhari, he explained that he has been in the trenches working on developing this construction technology, or “contech” to use the new jargon, for 11 years, having founded ST Bungalow LLC all the way back in 2013. With the support of the Hudson Valley Venture Hub (HVVH), which provided invitations to events, counseling, and PR, the company has been able to advance its innovative product. Their goals for the remainder of the year include prototyping and product certification, laying the groundwork for future growth. Over the next year or so, ST Bungalow aims to scale quickly by utilizing recycled wind blade materials, which are both affordable and environmentally friendly. This vision is driven by market demand, and the company plans to grow through marketing and licensing. Based in the Hudson Valley, where the founders reside, the company’s partnership with the University of Maine has also been instrumental in their journey.

As the industry moves towards more stringent environmental standards, this breakthrough construction technology system offers a versatile, cost-efficient, and eco-friendly alternative for reinforcing concrete in various construction projects.

For further information, contact Ashok Chaudhari at ashok@solartecticllc.com

Written by Lorena Marron, Senior Marketing Research Aide at the Hudson Valley Venture Hub. Undergraduate student at SUNY New Paltz, majoring in Marketing and International Business.

Newsletter Archive: | March 2019 | April 2019 | May 2019 | June 2019 | July 2019 | August 2019 | September 2019 | October 2019 | November 2019 | January 2020 | February 2020 | March 2020 | April 2020 | May 2020 | June 2020 | July 2020 | August 2020 | September 2020 | October 2020 | November 2020 | February 2021 | March 2021 | April 2021 | May 2021 | June 2021 | July 2021 | August 2021 | September 2021 | October 2021 | November 2021 | December 2021 | January 2022 | February 2022 | March 2022 | July 2022 | August 2022 | February 2023